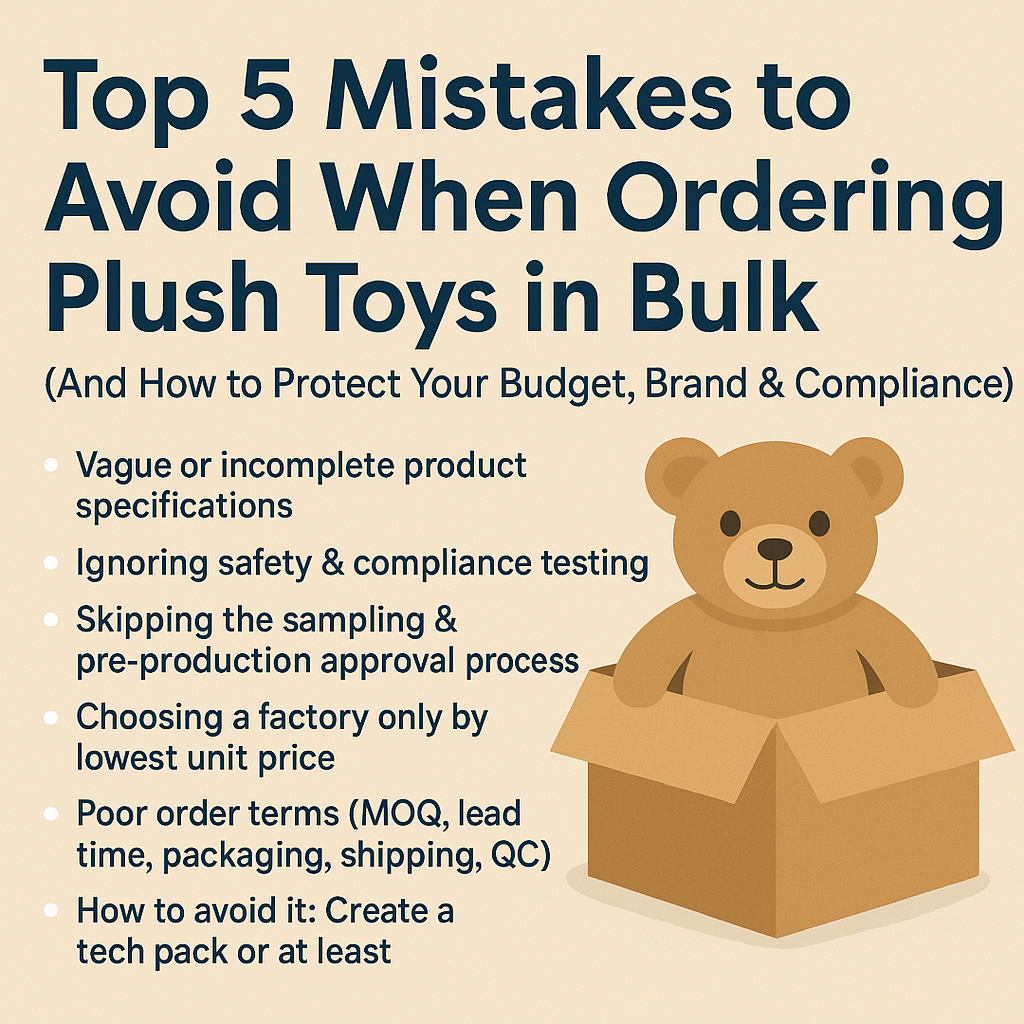

(And How to Protect Your Budget, Brand & Compliance)

Ordering plush toys in bulk is not the same as buying a few samples online. When you scale up—whether for retail, licensing, promotions, or private label—you face quality risk, safety regulations, timeline pressure, and hidden costs. As a plush toy manufacturer in China, we’ve seen the same problems cause avoidable delays, chargebacks, and even seized shipments at customs

Below are the top 5 mistakes buyers make when sourcing or manufacturing plush toys in bulk—plus practical ways to avoid them.

Mistake 1: Vague or Incomplete Product Specifications

“We want a 20cm bear, soft fabric, good quality.” ← This is not a spec.

When details are unclear, every factory will guess differently—leading to inconsistent samples, price changes, and disputes after mass production.

Key specs you must define:

- Finished size (standing / seated)

- Fabrics (plush pile length, minky, velboa, recycled polyester, organic cotton)

- Stuffing type & firmness

- Embroidery vs. print vs. heat-transfer logo

- Color references (Pantone TCX preferred)

- Safety requirements (age grade: 0+, 3+, etc.)

- Packaging (polybag, hangtag, display box)

- Labeling (care label, country of origin, fiber content)

How to avoid it: Create a tech pack or at least a PDF with drawings, photos, dimensions, Pantone colors, and branding placement. Confirm both English + annotated images.

Mistake 2: Ignoring Safety & Compliance Testing (EN71 / ASTM / CPSIA)

Skipping compliance is the fastest way to lose money. Many countries (U.S., EU, U.K., Canada, Australia) require children’s plush toys to meet specific safety standards—flammability, small parts, heavy metals, labeling.

Common standards:

- EN71 (Europe)

- ASTM F963 & CPSIA (United States)

- CE Marking requirements (EU retail)

- REACH / phthalate limits

Risks if ignored: Customs holds, recalls, fines, product destruction, brand damage.

How to avoid it:

- Confirm materials are compliant before mass order.

- Request material test reports or book 3rd-party lab testing (SGS, Intertek, TÜV).

- Send Pre-Production (PP) sample for testing—not just lab-dip fabric.

Mistake 3: Skipping the Sampling & Pre-Production Approval Process

Some buyers approve the first sample and then go straight to mass order—only to discover color variation, stiff stuffing, wrong logo, or loose stitching in 10,000 pcs.

Recommended sampling flow:

- Concept sketch / reference sample

- 1st prototype – shape & proportions

- Revised sample – fabric, embroidery, color

- Pre-Production (PP) sample – final approved version used as production master

- Golden sample sealed & signed by both buyer + factory

Tip: Keep one golden sample at the factory and one in your office. Production QC compares to this master.

Mistake 4: Choosing a Factory Only by Lowest Unit Price

Low price can hide high cost later: weak stitching, color bleed, shedding fur, failed safety testing, carton damage, or shipment rework. Replacements + air freight = disaster.

Look beyond unit price:

- Fabric GSM & pile quality

- Thread count & seam strength

- Colorfastness test

- Stuffing weight per piece

- Passed third-party inspection?

- Warranty / remake policy

Total landed cost matters: Unit price + tooling + compliance testing + freight + duty + rework = real cost. Paying a little more for reliable OEM plush toy manufacturing often saves money overall.

Mistake 5: Poor Order Terms (MOQ, Lead Time, Packaging, Shipping, QC)

Many problems come from things never discussed up front. Clarify these in writing:

Before placing PO, confirm:

- MOQ per style / color

- Production lead time (sample approval date start?)

- Payment terms (deposit %, balance timing)

- Inspection (AQL level? Third-party allowed?)

- Packaging spec (inner polybag, hangtag, master carton qty)

- Labeling requirements (UPC, CE, care label language)

- Shipping terms (EXW, FOB Shanghai, CIF, DDP?)

- Import documents needed (Form A, COO, test reports)

Pro tip: Use a structured Purchase Order (PO) + Spec Sheet. Attach approved photos and golden sample references to reduce disputes.

Quick Checklist Before You Confirm Bulk Production

| Item | Confirmed? | Notes |

|---|---|---|

| Tech pack with size, materials, colors | ☐ | |

| Safety compliance standard chosen | ☐ | EN71 / ASTM / CPSIA |

| PP sample approved & sealed | ☐ | |

| Testing booked or reports received | ☐ | |

| MOQ / lead time in contract | ☐ | |

| Packaging + labeling finalized | ☐ | |

| Inspection plan before shipment | ☐ |

Copy this into Excel or Google Sheets and use it with every order.

Frequently Asked Questions (Buyers Ask Us)

Q: When should testing be done?

After PP sample approval, before mass production—or at least before shipping.

Q: What’s a reasonable lead time?

Typically 25–60 days after sample approval, depending on complexity and order quantity.

Final Thoughts: Avoid Mistakes, Protect Your Brand

Bulk plush toy orders go smoothly when specs are clear, safety is tested, and communication is documented. As a custom plush toy manufacturer in Yangzhou, China, FUToys supports brands, importers, retailers, and promotional companies worldwide with OEM/ODM service, low MOQ options, and compliance support.

Planning a bulk order? Send us your design or idea—we’ll review specs, flag risk points, and give you a quote.

Contact FUToys: Request samples, compliance testing support, or cost analysis for your next plush project.